A duplex laminator will joins 2 layer of web, a triplex lamination machine will join 3 layers together in 1 pass. Coating machines are used to apply a layer of coated material onto a web (support).

Ask more informations

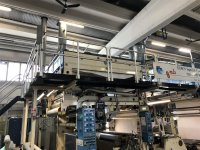

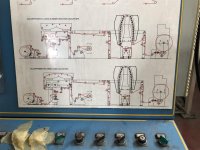

- Machine Code

- LA356

- Manufacturer

- MB

- Modello

- HOT MELT, WAX COATER LAMINATOR

- Year

- 2002

- Application

- Lamination + coating

- Type of lamination/coating

- HOT MELT

- Working width (mm)

- 1700

- Materials

- Paper and board, Film and Alu foil ( secondary unwi)

- Speed

- 400 mpm

- First unwinder type

- Single position shaftless double brake for paper and board

- Max diameter reel unwinder

- 1900

- Secondary unwinder type

- Single position shaftles for film and Al foil

- Max diameter reel unwinder

- 1000

- Rewinder type

- Surface driven shaftless

- Max diameter reel rewinder

- 1900

- Coating unit

- Trolley based with Wax - Hot melt trolley and Semi flexo trolley

- Second Coating unitr

- Gravure for Primer coating

- Drying

- 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley . Primer Gravure unit is equippe d with double hood eac 3 mt length 18 blowing air slots, 2 blowing fabns , one exhaust fan , two gas burners and automatic recirculation unoit and NIRA LEL control

- pumping mixing unit

- Prmelting unot Nordson for Wax coating

- Coating rollers

- 6 anilox rollers and 40 sleeves for gravure coating nip roll

- Note

- Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line

| Machine Code | LA356 |

| Manufacturer | MB |

| Modello | HOT MELT, WAX COATER LAMINATOR |

| Year | 2002 |

| Application | Lamination + coating |

| Type of lamination/coating | HOT MELT |

| Working width (mm) | 1700 |

| Materials | Paper and board, Film and Alu foil ( secondary unwi) |

| Speed | 400 mpm |

| First unwinder type | Single position shaftless double brake for paper and board |

| Max diameter reel unwinder | 1900 |

| Secondary unwinder type | Single position shaftles for film and Al foil |

| Max diameter reel unwinder | 1000 |

| Rewinder type | Surface driven shaftless |

| Max diameter reel rewinder | 1900 |

| Coating unit | Trolley based with Wax - Hot melt trolley and Semi flexo trolley |

| Second Coating unitr | Gravure for Primer coating |

| Drying | 3 meter tunnel with one blowing and one exhaus fan and one gas burner for lamination unit with semiflexo trolley . Primer Gravure unit is equippe d with double hood eac 3 mt length 18 blowing air slots, 2 blowing fabns , one exhaust fan , two gas burners and automatic recirculation unoit and NIRA LEL control |

| pumping mixing unit | Prmelting unot Nordson for Wax coating |

| Coating rollers | 6 anilox rollers and 40 sleeves for gravure coating nip roll |

| Note | Possible operation 1) Wax Coating laminating Paper - Alu foil or paper film and primer in line 2) Wax paper coating one side or doiuble side 3) Hot melt coating 4) Water based lamination wet bond paper -Alu foil with semiflexo trolley and primer in line |

KYMC COMBI 1300

-

Machine Code: LA450

-

Year: 2006

-

Working width (mm): 1300

POLYTYPE Polynorm II

-

Machine Code: LA485

-

Year: 1982

-

Working width (mm): 1280

GENERAL CONVERTING MACHINES

-

Machine Code: LA490

-

Year: 2014

-

Working width (mm): 1400

NORDMECCANICA TRIPLEX COMBI

-

Machine Code: LA388

-

Year: 1998

-

Working width (mm): 1400

ITALFLEX 2000-80

-

Machine Code: LA391

-

Year: 2001

-

Working width (mm): 900

DCM Laminastar 2

-

Machine Code: LA306

-

Year: 2000

-

Working width (mm): 1300