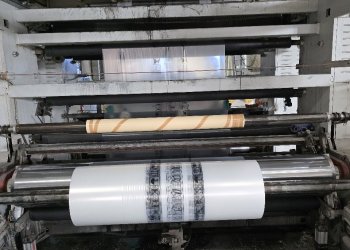

Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

- EX767

- Manufacturer

- KUNG HSING

- Modello

- KS-AE50 / VOLTAGE 380V-50HZ

- Year

- 2015

- Number of layers

- 1

- Film structure

- A

- Material

- HDPE; LDPE

- Film Width

- 700

- Output (Kg/h)

- 60kg/h

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 50mm

- Bubble cage

- Yes

- Panel for gussets

- Yes

- Corona treatment

- Yes

- Web guide

- Yes

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 800

- Note

- Thickness: 12 microns – 125 microns Screen Changer: Manual / 50 Heigth: 6 m

| Machine Code | EX767 |

| Manufacturer | KUNG HSING |

| Modello | KS-AE50 / VOLTAGE 380V-50HZ |

| Year | 2015 |

| Number of layers | 1 |

| Film structure | A |

| Material | HDPE; LDPE |

| Film Width | 700 |

| Output (Kg/h) | 60kg/h |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 50mm |

| Bubble cage | Yes |

| Panel for gussets | Yes |

| Corona treatment | Yes |

| Web guide | Yes |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 800 |

| Note | Thickness: 12 microns – 125 microns Screen Changer: Manual / 50 Heigth: 6 m |

WINDMÖLLER & HÖLSCHER Only extrusion head

-

Machine Code: EX673

-

Year: 2000

ALPINE UNEX 62/90/Aç

-

Machine Code: EX765

-

Year: 2003

-

Film Width: 1800

REIFENHAUSER RT371

-

Machine Code: EX714

-

Year: 1989

-

Film Width: 1300