** SOLD **

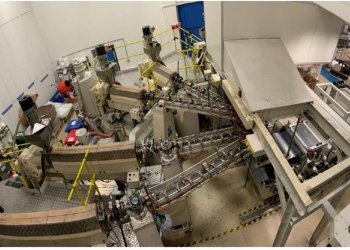

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

about a similar one

- Machine Code

- CA165

- Manufacturer

- SML

- Year

- 2010

- Number of layers

- 3

- Material

- CPP

- Film width (mm)

- 2400

- Output (Kg/h)

- 620 kg/h

- Screw diam 1

- 135 mm

- Chill roll unit

- 1000 mm diam

- Corona treatment

- Yes, Mero

- Note

- The line has been ordered in 2010 and installed in 2011 3 layers: B/C/A 15%-70%-15% o 20%-60%-20% thickness: 18-100 micron Extruders : 135 diam mm/ l/d33 output620 kg/h 75 / 33 200 kg/h 75 / 33 200 kg/h On the CPP line are installed: IR measuring system: Electronic Systems Gravimetric system: DOTECO

| Machine Code | CA165 |

| Manufacturer | SML |

| Year | 2010 |

| Number of layers | 3 |

| Material | CPP |

| Film width (mm) | 2400 |

| Output (Kg/h) | 620 kg/h |

| Screw diam 1 | 135 mm |

| Chill roll unit | 1000 mm diam |

| Corona treatment | Yes, Mero |

| Note | The line has been ordered in 2010 and installed in 2011 3 layers: B/C/A 15%-70%-15% o 20%-60%-20% thickness: 18-100 micron Extruders : 135 diam mm/ l/d33 output620 kg/h 75 / 33 200 kg/h 75 / 33 200 kg/h On the CPP line are installed: IR measuring system: Electronic Systems Gravimetric system: DOTECO |

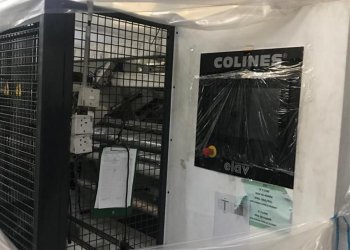

COLINES HANDrollEX 1000A

-

Machine Code: CA200

-

Year: 2009

-

Film width (mm): 1000

COLINES ALL ROLL EX 1500

-

Machine Code: CA215

-

Year: 2017

-

Film width (mm): 1500

TECHNO COATING ENGINEERING

-

Machine Code: CA168

-

Year: 1999

-

Film width (mm): 3000