- Código Máquina

- CA142

- Constructor

- TECHNO COATING ENGINEERING

- Año

- 2001

- Number of layers

- 5

- Material

- Stretch film LLDPE

- Film width (mm)

- 3000

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 130 mm

- Description 1

- L/D 30; Bimetallic barrel; Gravimetric doser; Motor 250Kw; hydraulic screen changer

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 160 mm

- Description 2

- L/D 30; Bimetallic barrel; Gravimetric doserc; Motor 350Kw; 2x forced feeding for edge trim re-feeding system 130mm L/D6; hydraulic screen changer

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 160 mm

- Description 3

- L/D 30; Bimetallic barrel; Gravimetric doser; Motor 350Kw; hydraulic screen changer

- Extruder 4 Layer ref:

- D

- Screw diam 4

- 130 mm

- Description 4

- L/D 30; Bimetallic barrel; Gravimetric doser; Motor 250Kw; hydraulic screen changer

- Head description

- Automatic die, Flex lip and thermobolt. Make EDI model: Autoflex 3700 m/m IV H40;Year 2010 . Die gap 0,1-1mm; Vacuum Box

- Die width (mm)

- 3700

- Chill roll unit

- chill roll width 3800mm; firs chill roll diameter 980mm; Electrostati edge pinning system ELTEX;

- Thickness controll system

- Automatic. Make Electronic System model CTW-5000 ; double gauge thickness reading system with Beta rays, complete with control panel and feedback on thermobolts system

- Web guide

- E+L

- Rewinder description

- Rewinder for Jumbo reels and machine reels. Automaticreel change, reels extraction and new core position system. contact roller diam 495mm;

- Note

- Water termoregutation and pumping unit - Edge trim and in line re-feeding system into B extruder - Components : Drives : SIEMENS INVERTERS : SIEMENS Relais temporized : Weimuller Pneumatic components : CEMA Hydraulic components : Norgen Ball bearings : SKF Motors DC : SIEMENS Motors AC : Bima/SIEMENS Available several spare parts among which a spare die.

| Código Máquina | CA142 |

| Constructor | TECHNO COATING ENGINEERING |

| Año | 2001 |

| Number of layers | 5 |

| Material | Stretch film LLDPE |

| Film width (mm) | 3000 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 130 mm |

| Description 1 | L/D 30; Bimetallic barrel; Gravimetric doser; Motor 250Kw; hydraulic screen changer |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 160 mm |

| Description 2 | L/D 30; Bimetallic barrel; Gravimetric doserc; Motor 350Kw; 2x forced feeding for edge trim re-feeding system 130mm L/D6; hydraulic screen changer |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 160 mm |

| Description 3 | L/D 30; Bimetallic barrel; Gravimetric doser; Motor 350Kw; hydraulic screen changer |

| Extruder 4 Layer ref: | D |

| Screw diam 4 | 130 mm |

| Description 4 | L/D 30; Bimetallic barrel; Gravimetric doser; Motor 250Kw; hydraulic screen changer |

| Head description | Automatic die, Flex lip and thermobolt. Make EDI model: Autoflex 3700 m/m IV H40;Year 2010 . Die gap 0,1-1mm; Vacuum Box |

| Die width (mm) | 3700 |

| Chill roll unit | chill roll width 3800mm; firs chill roll diameter 980mm; Electrostati edge pinning system ELTEX; |

| Thickness controll system | Automatic. Make Electronic System model CTW-5000 ; double gauge thickness reading system with Beta rays, complete with control panel and feedback on thermobolts system |

| Web guide | E+L |

| Rewinder description | Rewinder for Jumbo reels and machine reels. Automaticreel change, reels extraction and new core position system. contact roller diam 495mm; |

| Note | Water termoregutation and pumping unit - Edge trim and in line re-feeding system into B extruder - Components : Drives : SIEMENS INVERTERS : SIEMENS Relais temporized : Weimuller Pneumatic components : CEMA Hydraulic components : Norgen Ball bearings : SKF Motors DC : SIEMENS Motors AC : Bima/SIEMENS Available several spare parts among which a spare die. |

MACCHI

-

Código Máquina: CA171

-

Año: 2012

-

Film width (mm): 2000

ADTECH PROVERA HR 1000/3

-

Código Máquina: CA206

-

Año: 2005

-

Film width (mm): 1000

TECHNO COATING ENGINEERING

-

Código Máquina: CA143

-

Año: 2001

-

Film width (mm): 3000

DOLCI FCL-5/H5

-

Código Máquina: CA251

-

Año: 2008

-

Film width (mm): 2000

ADTECH PROVERA

-

Código Máquina: CA205

-

Año: 2003

-

Film width (mm): 1500

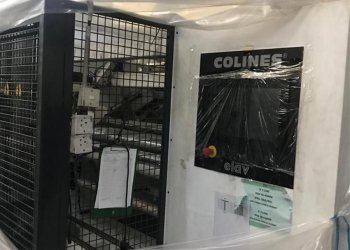

COLINES ALL ROLL EX 1500

-

Código Máquina: CA215

-

Año: 2017

-

Film width (mm): 1500