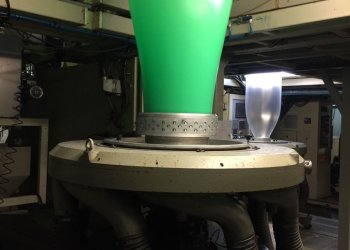

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

- Machine Code

- EX746

- Manufacturer

- WINDMÖLLER & HÖLSCHER

- Modello

- VAREX

- Year

- 2012

- Number of layers

- 9

- Material

- Barrier film

- Film Width

- 2200

- Extruder 1 Layer ref:

- 2 EXTRUDERS LAYER A AND B

- Screw diam 1

- 60mm L/D30

- Description 1

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 2 Layer ref:

- 2 EXTRUDERS LAYER C AND D

- Screw diam 2

- 60mm L/D30

- Description 2

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 3 Layer ref:

- E

- Screw diam 3

- 70mm L/D30

- Description 3

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 82KW , screw RPM 180. Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 4 Layer ref:

- F

- Screw diam 4

- 60mm L/D30

- Description 4

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 5 Layer ref:

- G

- Screw diam 5

- 60mm L/D30

- Description 5

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 6 Layer ref:

- H

- Screw diam 6

- 60mm L/D30

- Description 6

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Extruder 7 Layer ref:

- I

- Screw diam 7

- 60mm L/D30

- Description 7

- HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system

- Head description

- Model Maxicone 400 /550mm die range. Die lip heating , Multi cool air ring . Automatic Profile Control. Optifil P 2 K . IBC. Gap 1.25. 2.25mm

- Die diam (mm)

- 550mm

- Bubble cage

- Variocage size 740-2200mm. Centered and diameter, electronic adjustement

- Panel for gussets

- No

- Take off unit

- MULTINIP Film Haul-off system , Design oscillating type . Speed: 120 M/MIN : NOSTIC PACKAGE

- Corona treatment

- Yes, AFS suitable also for barrier film. Power 10 kW

- Web guide

- Edge guide

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1030mm

- Rewinder description

- Filmatic S model .Ultrasonic sensor for web edges. Surface/center winding with also gap winding mode without lay on roller. Anti static system. 6 inline slitting . Edge trim and station.

- Note

- 9 Module G gravimetric dosing system. Web break monitor. Film Cooling system Bubble collapsing unit with CRP path rollers in an extended design Path roller insulation for the path rollers of the collapsing station Path roller insulation for the path rollers of the cedge guide assembly 10 separate path rollers for film tube widths up to 2200mm Easy change package automatic size change over during production

| Machine Code | EX746 |

| Manufacturer | WINDMÖLLER & HÖLSCHER |

| Modello | VAREX |

| Year | 2012 |

| Number of layers | 9 |

| Material | Barrier film |

| Film Width | 2200 |

| Extruder 1 Layer ref: | 2 EXTRUDERS LAYER A AND B |

| Screw diam 1 | 60mm L/D30 |

| Description 1 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 2 Layer ref: | 2 EXTRUDERS LAYER C AND D |

| Screw diam 2 | 60mm L/D30 |

| Description 2 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 3 Layer ref: | E |

| Screw diam 3 | 70mm L/D30 |

| Description 3 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 82KW , screw RPM 180. Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 4 Layer ref: | F |

| Screw diam 4 | 60mm L/D30 |

| Description 4 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 5 Layer ref: | G |

| Screw diam 5 | 60mm L/D30 |

| Description 5 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 6 Layer ref: | H |

| Screw diam 6 | 60mm L/D30 |

| Description 6 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Extruder 7 Layer ref: | I |

| Screw diam 7 | 60mm L/D30 |

| Description 7 | HPS- Screws. Corrosion resistant chromium steel execution . AC drive. Motor 60KW , screw RPM 200 . Bimetal barrel. 4 heating zone . Contrac control .Temperature control for grooved feeding section up to 260 C. Hydraulic screen changers. Gravimetric dosing system |

| Head description | Model Maxicone 400 /550mm die range. Die lip heating , Multi cool air ring . Automatic Profile Control. Optifil P 2 K . IBC. Gap 1.25. 2.25mm |

| Die diam (mm) | 550mm |

| Bubble cage | Variocage size 740-2200mm. Centered and diameter, electronic adjustement |

| Panel for gussets | No |

| Take off unit | MULTINIP Film Haul-off system , Design oscillating type . Speed: 120 M/MIN : NOSTIC PACKAGE |

| Corona treatment | Yes, AFS suitable also for barrier film. Power 10 kW |

| Web guide | Edge guide |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1030mm |

| Rewinder description | Filmatic S model .Ultrasonic sensor for web edges. Surface/center winding with also gap winding mode without lay on roller. Anti static system. 6 inline slitting . Edge trim and station. |

| Note | 9 Module G gravimetric dosing system. Web break monitor. Film Cooling system Bubble collapsing unit with CRP path rollers in an extended design Path roller insulation for the path rollers of the collapsing station Path roller insulation for the path rollers of the cedge guide assembly 10 separate path rollers for film tube widths up to 2200mm Easy change package automatic size change over during production |

OMICRON COEX 3

-

Machine Code: EX605

-

Year: 1994

-

Film Width: 1600

DOLCI fIL 700

-

Machine Code: EX689

-

Year: 1990

-

Film Width: 3200

BANDERA Coex 7

-

Machine Code: EX781

-

Year: 2006

-

Film Width: 1800