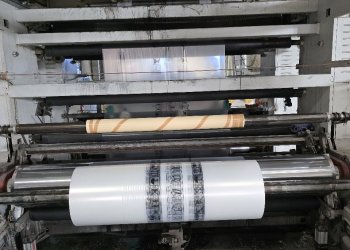

Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

- EX660

- Manufacturer

- REIFENHAUSER

- Modello

- Extrusion die

- Year

- 2004

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE , MDPE(blends)

- Head description

- Extrusion die only.

- Die diam (mm)

- 550mm gap 2,3mm

- Thickness controll system

- Not included

| Machine Code | EX660 |

| Manufacturer | REIFENHAUSER |

| Modello | Extrusion die |

| Year | 2004 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE , MDPE(blends) |

| Head description | Extrusion die only. |

| Die diam (mm) | 550mm gap 2,3mm |

| Thickness controll system | Not included |

DOLCI fIL 700

-

Machine Code: EX689

-

Year: 1990

-

Film Width: 3200

GHIOLDI - BANDERA

-

Machine Code: EX569

-

Year: 1990

-

Film Width: 1400

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX785

-

Year: 2002

-

Film Width: 800

MAM Z 2400 DW-SLW LD

-

Machine Code: EX766

-

Year: 2015

-

Film Width: 2400

REIFENHAUSER

-

Machine Code: EX637

-

Year: 2002

-

Film Width: 1800