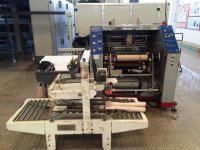

Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

- Machine Code

- CA132

- Manufacturer

- ADTECH PROVERA

- Year

- 2009

- Number of layers

- 3

- Film structure

- ABC

- Material

- Stretch film LLDPE

- Film width (mm)

- 2000

- Speed (m/min)

- 600

- Output (Kg/h)

- about 400 tons of stretch film per month

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 80mm

- Description 1

- L/D30, Hydraulic screen changer, AC motor, volumetric doser 2 comp

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 160mm

- Description 2

- L/D30, Hydraulic screen changer, AC motor

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 80mm

- Description 3

- L/D30, Hydraulic screen changer, AC motor, volumetric doser 2 comp

- Head description

- Automatic die with thermo bolts thickness profile control. Dual chamber vacuum box

- Chill roll unit

- first chill roll 1000mm diam, second 450mm diam, width 2550mm

- Thickness controll system

- Automatic thickness controll system. Gauge with x rays

- Web guide

- yes

- Rewinder description

- Turret type. Suitable for jumbo and machine rolls. Automatic reels unloading

- Note

- in line edge trim recovery system

| Machine Code | CA132 |

| Manufacturer | ADTECH PROVERA |

| Year | 2009 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | Stretch film LLDPE |

| Film width (mm) | 2000 |

| Speed (m/min) | 600 |

| Output (Kg/h) | about 400 tons of stretch film per month |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 80mm |

| Description 1 | L/D30, Hydraulic screen changer, AC motor, volumetric doser 2 comp |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 160mm |

| Description 2 | L/D30, Hydraulic screen changer, AC motor |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 80mm |

| Description 3 | L/D30, Hydraulic screen changer, AC motor, volumetric doser 2 comp |

| Head description | Automatic die with thermo bolts thickness profile control. Dual chamber vacuum box |

| Chill roll unit | first chill roll 1000mm diam, second 450mm diam, width 2550mm |

| Thickness controll system | Automatic thickness controll system. Gauge with x rays |

| Web guide | yes |

| Rewinder description | Turret type. Suitable for jumbo and machine rolls. Automatic reels unloading |

| Note | in line edge trim recovery system |

MACCHI

-

Machine Code: CA171

-

Year: 2012

-

Film width (mm): 2000

SUMITOMO

-

Machine Code: CA255

-

Year: 2010

-

Film width (mm): 2300

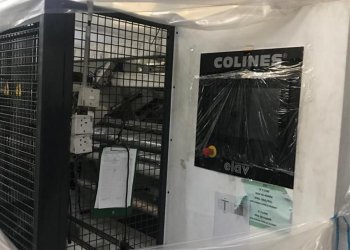

COLINES HANDrollEX 1000A

-

Machine Code: CA200

-

Year: 2009

-

Film width (mm): 1000

COLINES ALL ROLL EX 1500

-

Machine Code: CA215

-

Year: 2017

-

Film width (mm): 1500

COLINES POLYCAST CFC/210

-

Machine Code: CA243

-

Year: 2014

-

Film width (mm): 2100

ADTECH PROVERA HWR 1000/3

-

Machine Code: CA207

-

Year: 2008

-

Film width (mm): 1000