Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

- Machine Code

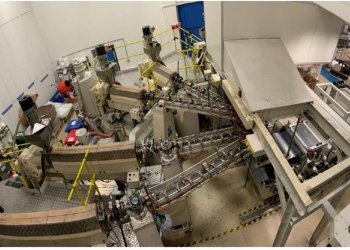

- CA231

- Manufacturer

- TECHNO COATING ENGINEERING

- Year

- 2005

- Number of layers

- 3

- Film structure

- ABC

- Material

- Stretch film LLDPE

- Film width (mm)

- 2000

- Output (Kg/h)

- 850 kg/h

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 100 mm AC motor 132 kW

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 160 mm AC motor 320 kW

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 100 mm AC motor 132 kW

- Head description

- Automatic Cloeren 2450 mm total width

- Chill roll unit

- 1000 mm diam

- Thickness controll system

- Electronic system 2 Beta sensors

- Rewinder description

- Machine reels, Hand reels

- Note

- Exact regranulating recycling unto for trims

| Machine Code | CA231 |

| Manufacturer | TECHNO COATING ENGINEERING |

| Year | 2005 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | Stretch film LLDPE |

| Film width (mm) | 2000 |

| Output (Kg/h) | 850 kg/h |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 100 mm AC motor 132 kW |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 160 mm AC motor 320 kW |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 100 mm AC motor 132 kW |

| Head description | Automatic Cloeren 2450 mm total width |

| Chill roll unit | 1000 mm diam |

| Thickness controll system | Electronic system 2 Beta sensors |

| Rewinder description | Machine reels, Hand reels |

| Note | Exact regranulating recycling unto for trims |

SUMITOMO

-

Machine Code: CA255

-

Year: 2010

-

Film width (mm): 2300

TECHNO COATING ENGINEERING 2000/5 PLUS 4E

-

Machine Code: CA125

-

Year: 2004

-

Film width (mm): 2000

ERWEPA

-

Machine Code: CA172

-

Year: 1993

-

Film width (mm): 1700

ADTECH PROVERA HWR 1000/3

-

Machine Code: CA207

-

Year: 2008

-

Film width (mm): 1000

COLINES POLYCAST CFC/210

-

Machine Code: CA243

-

Year: 2014

-

Film width (mm): 2100