- Codice Macchina

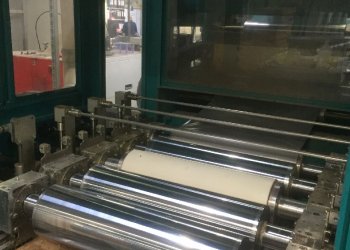

- LA427

- Manufacturer

- S.A.M.

- Year

- 2017

- Applicazione

- Lamination + coating

- Tipo di accoppiamento/spalmatura

- SOLVENT / WATER BASED

- Larghezza lavoro (mm)

- 1250

- Materiali

- Film, Paper , AL foil from 12 microns

- Tipo svolgitore primario

- Turret automatic

- Diametro massimo bobina svolgitore

- 1000

- Tipo svolgitore secondario

- Turret automatic

- Diametro massimo bobina svolgitore

- 1000

- Rewinder type

- Turret automatic

- Diametro massimo bobina avvolgitore

- 1000

- Unità di spalmatura

- Gravure coating unit sleeves type with trolley

- Seconda unità di spalmatura

- Gravure coating unit with gravure trolley and Semiflexo trolley Trolleys are interchangeable with station 1

- Essiccazione

- 1st coating unit - 2 zone drying section - total air inlet 7000 Nmc/h 1 vertical dryer 1,8 m Max T°C 120 and following 1 Horizontal Dryer 3 meter - Max T 150 °C Total installed power 300.000 Kcal /h 2nd coating unit 4 zones Drying section - Total air inlet 18.000 Nmc/h - 1 vertical dryer 3.0 m Max T°C 120 and following 3 horizontal dryers of 3 meters each Max T °C 150 - 200 - 150 Total installed power 800.000 Kcl/h

- Ulteriori informazioni

- Automatic LEL control for driers , Automatic Viscosity control , Chillers , CO2 fire extinguisher complete on the machine , Full ventilation system with thermal oil heat exchangers , Antistatic bars

| Codice Macchina | LA427 |

| Manufacturer | S.A.M. |

| Year | 2017 |

| Applicazione | Lamination + coating |

| Tipo di accoppiamento/spalmatura | SOLVENT / WATER BASED |

| Larghezza lavoro (mm) | 1250 |

| Materiali | Film, Paper , AL foil from 12 microns |

| Tipo svolgitore primario | Turret automatic |

| Diametro massimo bobina svolgitore | 1000 |

| Tipo svolgitore secondario | Turret automatic |

| Diametro massimo bobina svolgitore | 1000 |

| Rewinder type | Turret automatic |

| Diametro massimo bobina avvolgitore | 1000 |

| Unità di spalmatura | Gravure coating unit sleeves type with trolley |

| Seconda unità di spalmatura | Gravure coating unit with gravure trolley and Semiflexo trolley Trolleys are interchangeable with station 1 |

| Essiccazione | 1st coating unit - 2 zone drying section - total air inlet 7000 Nmc/h 1 vertical dryer 1,8 m Max T°C 120 and following 1 Horizontal Dryer 3 meter - Max T 150 °C Total installed power 300.000 Kcal /h 2nd coating unit 4 zones Drying section - Total air inlet 18.000 Nmc/h - 1 vertical dryer 3.0 m Max T°C 120 and following 3 horizontal dryers of 3 meters each Max T °C 150 - 200 - 150 Total installed power 800.000 Kcl/h |

| Ulteriori informazioni | Automatic LEL control for driers , Automatic Viscosity control , Chillers , CO2 fire extinguisher complete on the machine , Full ventilation system with thermal oil heat exchangers , Antistatic bars |

Coatema

-

Codice Macchina: LA469

-

Year: 2017

-

Larghezza lavoro (mm): 700

BIELLONI CLEO BIELLOFLEX

-

Codice Macchina: LA320

-

Year: 1994

-

Larghezza lavoro (mm): 1200

GENERAL CONVERTING MACHINES

-

Codice Macchina: LA490

-

Year: 2014

-

Larghezza lavoro (mm): 1400

CML MIRACH

-

Codice Macchina: LA361

-

Year: 2001

-

Larghezza lavoro (mm): 1250

DCM Laminastar 2

-

Codice Macchina: LA306

-

Year: 2000

-

Larghezza lavoro (mm): 1300

POLYTYPE POLYTYPE 522

-

Codice Macchina: LA348

-

Year: 1982

-

Larghezza lavoro (mm): 1040