- Code Machine

- CA152

- Fabricant

- PRIMPLAST

- Année

- 1999

- Number of layers

- 3

- Film structure

- ABC

- Material

- Stretch film LLDPE

- Film width (mm)

- 2000

- Speed (m/min)

- 550

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 120mm

- Description 1

- 30D . AC motor 400Kw mounted in axis. Screw extractor. 1 cartridge filter .Doteco gravimetric dosing system

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 120mm

- Description 2

- 30D . AC motor 200Kw.1 cartridge filter .Doteco gravimetric dosing system

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 90mm

- Description 3

- 30D . AC motor 110Kw mounted in axis. 1 cartridge filter.Doteco gravimetric dosing system

- Die width (mm)

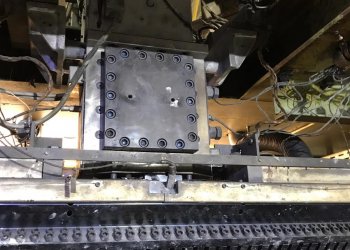

- 2480mm . Feedblock Cloeren. Flat die with 7+1 thermoregulating zones with 87 points for flexible lip regulation. Lip flex range 1mm. Fumes suction unit

- Chill roll unit

- max speed 550 m/min

- Rewinder max reel diameter (mm)

- 600mm

- Rewinder description

- Automatic winder mod. AVP 2.000-B .N 04+1 (spare) pneumatic shafts for cardboard cores int. diam. 76 mm with autocentering.Rolls unloading section — Automatic shafts loading/unloading.

- Note

- Inline scraps recovery extruder R120mm. Max suction speed 550m/min.AC motor 47 kw mounted in axis.Doteco gravimetric dosing system Set of pick-up manifolds and conveying pipes. Scraps grinder and air scraps separation unit with deadening jacket. Electro-aspirator unit with silencer and deadening box. Centrifugal separator for ground material. Electric fan for ground material conveyance. Deviating shutter for ground material discharge to the bags. 1 Air suction blade mod. PRIMPLAST (Vacuum box) • Plate steel body assembled on extrusion die. e Pipe set for blade/manifold connection. Motorized rear chamber adjustment Smoke collecting manifold with suction control shutter. N 0 2 electro-aspirator and connecting pipes to the manifold. N O 1 Single electroaspirator suitable for the suction on the extreme edge of the chambers. Edge keeping electrostatic device Positioning device with three axis adjustments Independent power supply with adjustment. X rays emission based thickness measurement system (SOTER]SCAN-TECH) Cooling System : Diam. 1.350 mm chill roll, equipped with a special water circulation system that guarantees a uniform surface temperature . Rubber coated roll with pneumatic control that allows the cleaning of the chill roll from extrusion fumes. Take-off complete with chromed/rubber coated roll 2 holders for thickness control unit. 1 a.c. motor reducer for chill roll driving. 1 a.c. motor reducer for take-off. Emergency push button set and accident prevention guards. Oscillating frame:2 aluminium rolls, one of which is treated. Max oscillation amplitude 100 mm on either sides.

| Code Machine | CA152 |

| Fabricant | PRIMPLAST |

| Année | 1999 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | Stretch film LLDPE |

| Film width (mm) | 2000 |

| Speed (m/min) | 550 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 120mm |

| Description 1 | 30D . AC motor 400Kw mounted in axis. Screw extractor. 1 cartridge filter .Doteco gravimetric dosing system |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 120mm |

| Description 2 | 30D . AC motor 200Kw.1 cartridge filter .Doteco gravimetric dosing system |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 90mm |

| Description 3 | 30D . AC motor 110Kw mounted in axis. 1 cartridge filter.Doteco gravimetric dosing system |

| Die width (mm) | 2480mm . Feedblock Cloeren. Flat die with 7+1 thermoregulating zones with 87 points for flexible lip regulation. Lip flex range 1mm. Fumes suction unit |

| Chill roll unit | max speed 550 m/min |

| Rewinder max reel diameter (mm) | 600mm |

| Rewinder description | Automatic winder mod. AVP 2.000-B .N 04+1 (spare) pneumatic shafts for cardboard cores int. diam. 76 mm with autocentering.Rolls unloading section — Automatic shafts loading/unloading. |

| Note | Inline scraps recovery extruder R120mm. Max suction speed 550m/min.AC motor 47 kw mounted in axis.Doteco gravimetric dosing system Set of pick-up manifolds and conveying pipes. Scraps grinder and air scraps separation unit with deadening jacket. Electro-aspirator unit with silencer and deadening box. Centrifugal separator for ground material. Electric fan for ground material conveyance. Deviating shutter for ground material discharge to the bags. 1 Air suction blade mod. PRIMPLAST (Vacuum box) • Plate steel body assembled on extrusion die. e Pipe set for blade/manifold connection. Motorized rear chamber adjustment Smoke collecting manifold with suction control shutter. N 0 2 electro-aspirator and connecting pipes to the manifold. N O 1 Single electroaspirator suitable for the suction on the extreme edge of the chambers. Edge keeping electrostatic device Positioning device with three axis adjustments Independent power supply with adjustment. X rays emission based thickness measurement system (SOTER]SCAN-TECH) Cooling System : Diam. 1.350 mm chill roll, equipped with a special water circulation system that guarantees a uniform surface temperature . Rubber coated roll with pneumatic control that allows the cleaning of the chill roll from extrusion fumes. Take-off complete with chromed/rubber coated roll 2 holders for thickness control unit. 1 a.c. motor reducer for chill roll driving. 1 a.c. motor reducer for take-off. Emergency push button set and accident prevention guards. Oscillating frame:2 aluminium rolls, one of which is treated. Max oscillation amplitude 100 mm on either sides. |

SUMITOMO

-

Code Machine: CA255

-

Année: 2010

-

Film width (mm): 2300

TECHNO COATING ENGINEERING

-

Code Machine: CA230

-

Année: 2001

-

Film width (mm): 2000

ERWEPA

-

Code Machine: CA172

-

Année: 1993

-

Film width (mm): 1700

MACCHI

-

Code Machine: CA171

-

Année: 2012

-

Film width (mm): 2000

TECHNO COATING ENGINEERING

-

Code Machine: CA231

-

Année: 2005

-

Film width (mm): 2000

ADTECH PROVERA

-

Code Machine: CA132

-

Année: 2009

-

Film width (mm): 2000