Biaxially oriented polypropylene (BOPP) and Biaxially oriented polyester (BOPET) are commonly produced in tender-frame lines. In these lines material is melted through a flat extrusion die (T-die) and solidified onto a cooled roller. Material is then stretched in machine direction in an MDO. Thereafter material is stretched in transversal direction in a TDO. These processes deliver a molecule orientation in both axes, this enhances many of their properties, particularly the mechanical, impact, barrier and optical properties.

Ask more informations

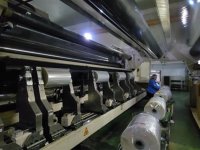

- Machine Code

- BO78

- Manufacturer

- BRUCKNER

- Year

- 2003

- Number of layers

- 4

- Material

- BOPP

- Output

- 2300 kg/hr

- Width (mm)

- 6350

- Extruder 1 Description

- Manufacturer Bandera, AC drive,

- Extruder 2 Description

- Manufacturer Bandera, AC drive,

- Extruder 3 Description

- Manufacturer Bandera, AC drive,

- Extruder 4 Description

- Manufacturer Bandera, AC drive,

- Head description

- Manufacturer: Simplas.Symmetrical design with three coat hangers.4 layers

- Thickness controll system

- Thickness Gauge NDC Brand,measurement range: 5 – 100my, IR Infrared

- Chill roll unit

- Film and chill roll drying system. Air knife.Water bath

- MDO description

- Manufacturer: Bruckner .14 pre-heating rolls . 6 stretching rolls .2 annealing rolls .9 nip rolls .Tension control at inlet and outlet .AC drive .Stretching ratio 1:1 / 1:8

- TDO description

- Manufacturer: Bruckner .Chain and chain track model: FOK 4.4.4 Heating system: circulating oil via individual heating system / zone (heat exchanger, fans, control valves , oil boiler, etc) .Edge guide system at inlet

- Pull roll unit

- Edge trim on-line recycling unit .2 corona treatment stations . AC drive

- Rewinder width

- 6350mm

- Rewinder description

- Working width: 6350 mm . Core o Steel cores, 6600 mm length .Max. mill roll diameter: 1300 mm

- Note

- Max mechanical speed: 250 m/min Packaging film Produced film type. Thickness: 15 - 60 micron. AC & PLC fully integrated system PLC with operator workstations Thickness Gauge NDC Brand,measurement range: 5 – 100my, IR Infrared Raw Material :material feeding equipment,pneumatic conveying system,cyclone to separate resin and conveying air,metal separator,mixing hopper,suction conveying for Co-Extruder Edge trim recycling : edge trim grinder Conveying fans

| Machine Code | BO78 |

| Manufacturer | BRUCKNER |

| Year | 2003 |

| Number of layers | 4 |

| Material | BOPP |

| Output | 2300 kg/hr |

| Width (mm) | 6350 |

| Extruder 1 Description | Manufacturer Bandera, AC drive, |

| Extruder 2 Description | Manufacturer Bandera, AC drive, |

| Extruder 3 Description | Manufacturer Bandera, AC drive, |

| Extruder 4 Description | Manufacturer Bandera, AC drive, |

| Head description | Manufacturer: Simplas.Symmetrical design with three coat hangers.4 layers |

| Thickness controll system | Thickness Gauge NDC Brand,measurement range: 5 – 100my, IR Infrared |

| Chill roll unit | Film and chill roll drying system. Air knife.Water bath |

| MDO description | Manufacturer: Bruckner .14 pre-heating rolls . 6 stretching rolls .2 annealing rolls .9 nip rolls .Tension control at inlet and outlet .AC drive .Stretching ratio 1:1 / 1:8 |

| TDO description | Manufacturer: Bruckner .Chain and chain track model: FOK 4.4.4 Heating system: circulating oil via individual heating system / zone (heat exchanger, fans, control valves , oil boiler, etc) .Edge guide system at inlet |

| Pull roll unit | Edge trim on-line recycling unit .2 corona treatment stations . AC drive |

| Rewinder width | 6350mm |

| Rewinder description | Working width: 6350 mm . Core o Steel cores, 6600 mm length .Max. mill roll diameter: 1300 mm |

| Note | Max mechanical speed: 250 m/min Packaging film Produced film type. Thickness: 15 - 60 micron. AC & PLC fully integrated system PLC with operator workstations Thickness Gauge NDC Brand,measurement range: 5 – 100my, IR Infrared Raw Material :material feeding equipment,pneumatic conveying system,cyclone to separate resin and conveying air,metal separator,mixing hopper,suction conveying for Co-Extruder Edge trim recycling : edge trim grinder Conveying fans |

WINDMÖLLER & HÖLSCHER W&H + Brückner CAST COEX TD3000

-

Machine Code: BO79

-

Year: 2002

-

Width (mm): 2800