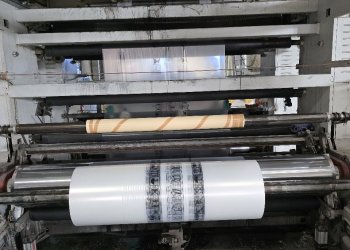

In a blown film extruder PE granulates (or other polymer) are melted in an extruder and pushed through a circular die extruding a tube of molten polymer. Tube is then inflated to multiples of its initial diameter and cooled to form a thin film. Bobble is later collapsed and re-winded.

Ask more informations

- Machine Code

- EX771

- Manufacturer

- BIELLONI

- Year

- 1998

- Number of layers

- 3

- Film Width

- 2000

- Output (Kg/h)

- 250 kg/h

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 65mm

- Description 1

- Gravimetric dosing unit Contrex M+S

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 80mm

- Description 2

- Gravimetric dosing unit Contrex M+S

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 65mm

- Description 3

- Gravimetric dosing unit Contrex M+S

- Die diam (mm)

- 400mm- gap.2,2

- Thickness controll system

- CONTREX

- Take off unit

- Oscillating

- Corona treatment

- FERRARINI

- Rewinder Type

- Double back to back

- Note

- Microperforator Total height 10 mt

| Machine Code | EX771 |

| Manufacturer | BIELLONI |

| Year | 1998 |

| Number of layers | 3 |

| Film Width | 2000 |

| Output (Kg/h) | 250 kg/h |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 65mm |

| Description 1 | Gravimetric dosing unit Contrex M+S |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 80mm |

| Description 2 | Gravimetric dosing unit Contrex M+S |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 65mm |

| Description 3 | Gravimetric dosing unit Contrex M+S |

| Die diam (mm) | 400mm- gap.2,2 |

| Thickness controll system | CONTREX |

| Take off unit | Oscillating |

| Corona treatment | FERRARINI |

| Rewinder Type | Double back to back |

| Note | Microperforator Total height 10 mt |

BATTENFELD

-

Machine Code: EX512

-

Year: 2003

-

Film Width: 2200

TECHNO COATING ENGINEERING

-

Machine Code: EX289

-

Year: 2001

-

Film Width: 2200

OMICRON COEX 3

-

Machine Code: EX605

-

Year: 1994

-

Film Width: 1600

BIELLONI Coex 3

-

Machine Code: EX764

-

Year: 1999

-

Film Width: 1700