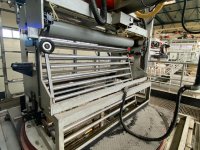

Blown film extrusion lines are commonly used to extrude plastic films for flexible packaging industry.

Ask more informations

- Machine Code

- EX764

- Manufacturer

- BIELLONI

- Modello

- Coex 3

- Year

- 1999

- Number of layers

- 3

- Film Width

- 1700

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 55mm L/D30

- Description 1

- Gravimetric doser and blender Plast Control (year 2011) 6 components

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 75mm L/D30

- Description 2

- Gravimetric doser and blender Plast Control (year 2011) 5 components

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 55mm L/D30

- Description 3

- Gravimetric doser and blender Plast Control (year 2011) 6 components

- Head description

- IBC

- Die diam (mm)

- 250mm

- Thickness controll system

- Plast Control (year 2011)

- Bubble cage

- Yes

- Take off unit

- Rotaring take off

- Corona treatment

- Ferrari & Benelli

- Web guide

- yes

- Rewinder Type

- Undefined

- Note

- CHILLER IBC and air ring

| Machine Code | EX764 |

| Manufacturer | BIELLONI |

| Modello | Coex 3 |

| Year | 1999 |

| Number of layers | 3 |

| Film Width | 1700 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 55mm L/D30 |

| Description 1 | Gravimetric doser and blender Plast Control (year 2011) 6 components |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 75mm L/D30 |

| Description 2 | Gravimetric doser and blender Plast Control (year 2011) 5 components |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 55mm L/D30 |

| Description 3 | Gravimetric doser and blender Plast Control (year 2011) 6 components |

| Head description | IBC |

| Die diam (mm) | 250mm |

| Thickness controll system | Plast Control (year 2011) |

| Bubble cage | Yes |

| Take off unit | Rotaring take off |

| Corona treatment | Ferrari & Benelli |

| Web guide | yes |

| Rewinder Type | Undefined |

| Note | CHILLER IBC and air ring |

KUNG HSING KS-AE50 / VOLTAGE 380V-50HZ

-

Machine Code: EX767

-

Year: 2015

-

Film Width: 700

WINDMÖLLER & HÖLSCHER VAREX

-

Machine Code: EX785

-

Year: 2002

-

Film Width: 800

BANDERA Coex 7

-

Machine Code: EX781

-

Year: 2006

-

Film Width: 1800