Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

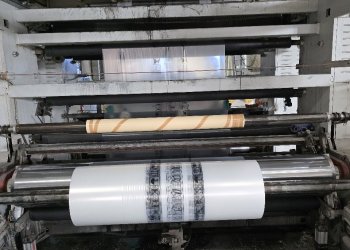

- Machine Code

- EX739

- Manufacturer

- MAM

- Year

- 1998

- Number of layers

- 3

- Material

- LLDPE,PEBD,PEMD

- Film Width

- 1800

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 70mm

- Description 1

- dosing unit Engin Plast

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 70mm

- Description 2

- dosing unit Engin Plast

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 70mm

- Description 3

- dosing unit Engin Plast

- Head description

- IBC,Eurochiller

- Die diam (mm)

- 220

- Thickness controll system

- K-design

- Web guide

- Yes

- Note

- Thickness min20my -max 200my

| Machine Code | EX739 |

| Manufacturer | MAM |

| Year | 1998 |

| Number of layers | 3 |

| Material | LLDPE,PEBD,PEMD |

| Film Width | 1800 |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 70mm |

| Description 1 | dosing unit Engin Plast |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 70mm |

| Description 2 | dosing unit Engin Plast |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 70mm |

| Description 3 | dosing unit Engin Plast |

| Head description | IBC,Eurochiller |

| Die diam (mm) | 220 |

| Thickness controll system | K-design |

| Web guide | Yes |

| Note | Thickness min20my -max 200my |

ALPINE UNEX 62/90/Aç

-

Machine Code: EX765

-

Year: 2003

-

Film Width: 1800

BIELLONI Coex 3

-

Machine Code: EX764

-

Year: 1999

-

Film Width: 1700