** SOLD **

Raw material most commonly used are low density polyethylene (LDPE) and High density polyethylene (HDPE). These are often used in blends with other polymers and additives.

Ask more informations

about a similar one

- Machine Code

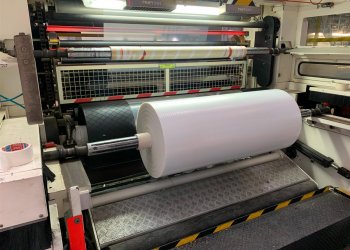

- EX665

- Manufacturer

- MACCHI

- Modello

- COEX3

- Year

- 2010

- Number of layers

- 3

- Film structure

- ABC

- Material

- LDPE, LLDPE Thicknes 20 - 200 microns

- Film Width

- 1700

- Output (Kg/h)

- 400 Kg / h

- Extruder 1 Layer ref:

- A

- Screw diam 1

- 65 / 30D

- Description 1

- 4 heating zones - AC motor 74 Kw- Hydraulic screen change gravimetric blendeer Doteco 5 comp

- Extruder 2 Layer ref:

- B

- Screw diam 2

- 100 / 30 D

- Description 2

- 5 heating zones -AC motor 180 Kw, hydraulic screen changer, gravimetric blendeer Doteco 5 comp

- Extruder 3 Layer ref:

- C

- Screw diam 3

- 65

- Description 3

- 4 heating zones - AC motor 74 Kw- Hydraulicscreen changer, gravimetric blendeer Doteco 5 comp

- Head description

- Coex Flex TE 503-; die range 300-500mm, IBC with Jet 6 system - blowing and exhaust fan 11kW controlled by inverters

- Die diam (mm)

- 400 gap 2mm

- Thickness controll system

- Automatic profil control, Plascontrol magic flow

- Bubble cage

- No marking system GSRC 2350/8 -5 with 5 lavels and 8 syncro arms with motorized remote controlled opening and height adjustment , 4 x Ultrasonic sensors for auto control of IBC,

- Panel for gussets

- Yes, motor driven

- Take off unit

- Oscillating ST 199- 1800oscillating width 1800 mm useful 1700 mm- S shape double cooling

- Corona treatment

- Yes

- Web guide

- E&L

- Rewinder Type

- Double back to back

- Rewinder max reel diameter

- 1200

- Rewinder description

- BOPLUS + Easy load - Roll diam 1200 mm

- Note

- TOWER STRUCTURE NOT INCLUDED total suggested height 15 mt Mechanical speed 150m/min Total installed power 540 Kw Recotrim recycling system

| Machine Code | EX665 |

| Manufacturer | MACCHI |

| Modello | COEX3 |

| Year | 2010 |

| Number of layers | 3 |

| Film structure | ABC |

| Material | LDPE, LLDPE Thicknes 20 - 200 microns |

| Film Width | 1700 |

| Output (Kg/h) | 400 Kg / h |

| Extruder 1 Layer ref: | A |

| Screw diam 1 | 65 / 30D |

| Description 1 | 4 heating zones - AC motor 74 Kw- Hydraulic screen change gravimetric blendeer Doteco 5 comp |

| Extruder 2 Layer ref: | B |

| Screw diam 2 | 100 / 30 D |

| Description 2 | 5 heating zones -AC motor 180 Kw, hydraulic screen changer, gravimetric blendeer Doteco 5 comp |

| Extruder 3 Layer ref: | C |

| Screw diam 3 | 65 |

| Description 3 | 4 heating zones - AC motor 74 Kw- Hydraulicscreen changer, gravimetric blendeer Doteco 5 comp |

| Head description | Coex Flex TE 503-; die range 300-500mm, IBC with Jet 6 system - blowing and exhaust fan 11kW controlled by inverters |

| Die diam (mm) | 400 gap 2mm |

| Thickness controll system | Automatic profil control, Plascontrol magic flow |

| Bubble cage | No marking system GSRC 2350/8 -5 with 5 lavels and 8 syncro arms with motorized remote controlled opening and height adjustment , 4 x Ultrasonic sensors for auto control of IBC, |

| Panel for gussets | Yes, motor driven |

| Take off unit | Oscillating ST 199- 1800oscillating width 1800 mm useful 1700 mm- S shape double cooling |

| Corona treatment | Yes |

| Web guide | E&L |

| Rewinder Type | Double back to back |

| Rewinder max reel diameter | 1200 |

| Rewinder description | BOPLUS + Easy load - Roll diam 1200 mm |

| Note | TOWER STRUCTURE NOT INCLUDED total suggested height 15 mt Mechanical speed 150m/min Total installed power 540 Kw Recotrim recycling system |