Cast film extrusion lines are commonly used to extrude plastic films especially for flexible packaging industry. / In a cast film extruder PE, PP or PA granulates (or other polymers) are melted inro an extruder and pushed through a flat extrusion die (T die), extruding a sheet of molten polymer onto a cooled roller (chill roll).

Ask more informations

- Machine Code

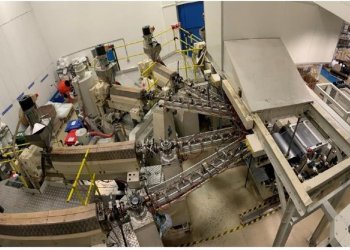

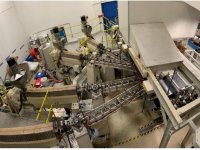

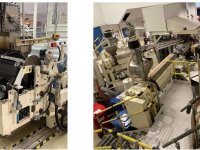

- CA247

- Manufacturer

- BETOL

- Year

- 1994

- Number of layers

- 7

- Film structure

- EDBBCAA ; EBBCDCA ; ACEDEBA

- Film width (mm)

- 650

- Output (Kg/h)

- 200

- Note

- Hoppers and pneumatic feeding system available Pipe design Scren changer

| Machine Code | CA247 |

| Manufacturer | BETOL |

| Year | 1994 |

| Number of layers | 7 |

| Film structure | EDBBCAA ; EBBCDCA ; ACEDEBA |

| Film width (mm) | 650 |

| Output (Kg/h) | 200 |

| Note | Hoppers and pneumatic feeding system available Pipe design Scren changer |

WINDMÖLLER & HÖLSCHER FILMEX

-

Machine Code: CA133

-

Year: 1999

-

Film width (mm): 1760

ADTECH PROVERA HR 1000/3

-

Machine Code: CA206

-

Year: 2005

-

Film width (mm): 1000

DOLCI FCL-5/H5

-

Machine Code: CA251

-

Year: 2008

-

Film width (mm): 2000

TECHNO COATING ENGINEERING

-

Machine Code: CA168

-

Year: 1999

-

Film width (mm): 3000

MACCHI

-

Machine Code: CA235

-

Year: 1999

-

Film width (mm): 1500

MACCHI

-

Machine Code: CA171

-

Year: 2012

-

Film width (mm): 2000