Flexo presses are used to print on different supports: plastic films, paper and aluminium foil.

Ask more informations

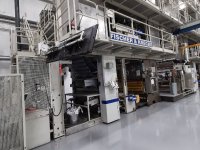

- Machine Code

- FL1130

- Manufacturer

- FISCHER & KRECKE

- Modello

- F16 S

- Year

- 2001

- Number of colors

- 8

- Print possibilityes

- 8 col print + 1 Gravure Coating lamination unit + 1 Gravure coating in register

- Gearless

- Yes

- Fast sleeve change

- Yes

- 4 motor per deck CNC position system

- Yes

- Computer supervision

- Yes

- Web width (mm)

- 1400

- Print width (mm)

- 1350

- Min print repeat (mm)

- 320

- Max print repeat (mm)

- 800

- Unwinder type

- Turret Automatic with roll loading system

- Max reel diameter unwinder (mm)

- 1000

- Rewinder type

- Turret Automatic with roll unloading system

- Max reel diameter rewinder (mm)

- 1000

- Drying

- CI section 2 zone s - 4 fans 5 mt tunnel - 1st Gravure unit 2 zones with 2 x 6 mt hoods totally 12 mt - 2nd Gravure coating unit 2 zones with 2 x 6 mt hoods totally 12 mt

- Videocamera

- Yes BST ELTROMAT new 2018

- Corona treatment

- 3 corona treaters driven

- Web guides

- 4 before print section and one before each gravure unit

- Vyscosity control

- Bloss Viscosity Control System Viscolor 2200

- Washing system

- Yes FK Autoclean

- Inking system

- Closed chamber doctor blades

- Anilox

- 18

- Print Sleeves

- 32

- Note

- Additional secondary Turret unwinder diam 1000 mm for lamination film

| Machine Code | FL1130 |

| Manufacturer | FISCHER & KRECKE |

| Modello | F16 S |

| Year | 2001 |

| Number of colors | 8 |

| Print possibilityes | 8 col print + 1 Gravure Coating lamination unit + 1 Gravure coating in register |

| Gearless | Yes |

| Fast sleeve change | Yes |

| 4 motor per deck CNC position system | Yes |

| Computer supervision | Yes |

| Web width (mm) | 1400 |

| Print width (mm) | 1350 |

| Min print repeat (mm) | 320 |

| Max print repeat (mm) | 800 |

| Unwinder type | Turret Automatic with roll loading system |

| Max reel diameter unwinder (mm) | 1000 |

| Rewinder type | Turret Automatic with roll unloading system |

| Max reel diameter rewinder (mm) | 1000 |

| Drying | CI section 2 zone s - 4 fans 5 mt tunnel - 1st Gravure unit 2 zones with 2 x 6 mt hoods totally 12 mt - 2nd Gravure coating unit 2 zones with 2 x 6 mt hoods totally 12 mt |

| Videocamera | Yes BST ELTROMAT new 2018 |

| Corona treatment | 3 corona treaters driven |

| Web guides | 4 before print section and one before each gravure unit |

| Vyscosity control | Bloss Viscosity Control System Viscolor 2200 |

| Washing system | Yes FK Autoclean |

| Inking system | Closed chamber doctor blades |

| Anilox | 18 |

| Print Sleeves | 32 |

| Note | Additional secondary Turret unwinder diam 1000 mm for lamination film |

FLEXOTECNICA TACHYS

-

Machine Code: FL1101

-

Year: 2003

-

Web width (mm): 1250

SCHIAVI BOBST RIGEL

-

Machine Code: FL1069

-

Year: 2001

-

Web width (mm): 1320

UTECO EMERALD 825 MOD 120

-

Machine Code: FL0662

-

Year: 1999

-

Web width (mm): 1250

FLEXOTECNICA TACHYS FNC-3000-100

-

Machine Code: FL0841

-

Year: 1999

-

Web width (mm): 1050

UTECO TOPAZ 608

-

Machine Code: FL0927

-

Year: 2011

-

Web width (mm): 1350

UTECO ONYX 808

-

Machine Code: FL1145

-

Year: 2010

-

Web width (mm): 1350